Pipette Molding

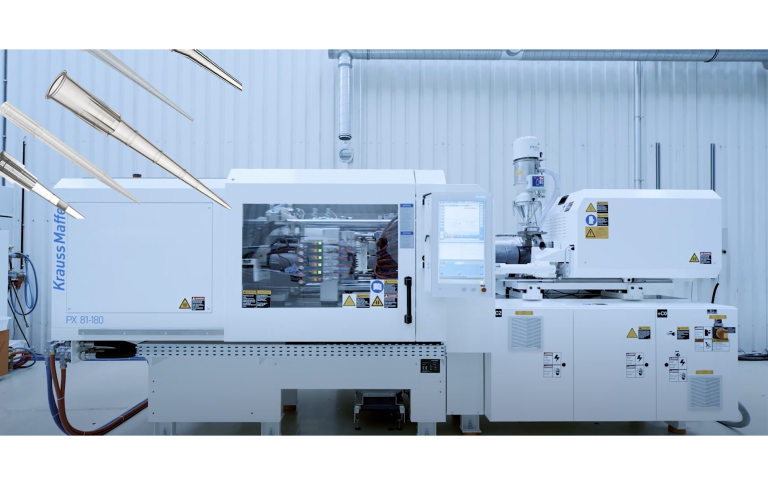

Pipette Molding Krauss Maffei PX Electric Machine Click here for the PX web page This machine is an 80 metric ton wide platen machine Complete with Medical Molding features Raised for easy cleaning Closed lubrication of the toggle Grease-free, chrome-plated tiebars Automatic central lubrication Complete encapsulation of all drives Qualification support